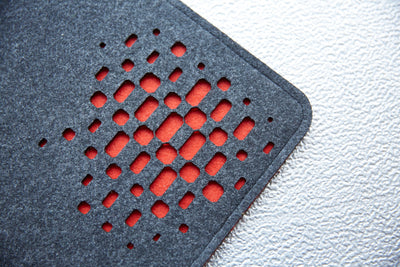

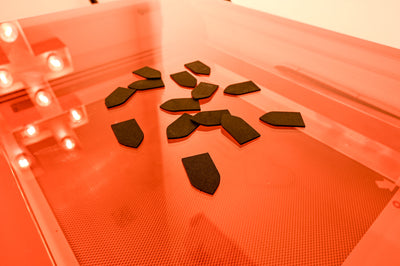

Various materials are used in orthopaedic technology to produce orthopaedic devices. With the Mr Beam laser cutter, you get a tool that allows you to be flexible in your work at all times. In this way, you can significantly reduce the waiting time of your patients because you can quickly take care of different solutions yourself. This then happens extremely precisely and automatically. The following applications are perfect for our Mr Beam:

![Mr Beam dreamcut [x] Lasercutter](http://www.mr-beam.org/cdn/shop/files/mr-beam-dreamcut-x-laser-hero.jpg?v=1704362921&width=2400)