A fibre laser is a laser in which the endowed core of a glass fibre acts as an active medium. This glass fibre has light wave conductor properties and consists of several layers. For this reason, the fibre can not only guide the laser beam unhindered, but also continuously intensify. The quality and intensity of the escaping radiation is very high. So the fibre laser can be used anywhere where it depends on quick and intensive processing of surfaces.

How is a fibre laser built?

Each single fibre has different layers, with the main part of quartz glass and is covered with a thin plastic layer. The refractive index decreases from the inside out. This can be observed with every layer and forms the basis for perfect lighting. Of the Resonator of the fibre laser consists either two additional mirrors or Fibre Bragg grids grilles that are inserted into the wave conductor. This is done using UV radiation. The number of crowds at the core of a fibre differed significantly. There are areas with high and areas with low breed numbers. After leaving an active fibre, a laser beam comes into the glass fibre. In addition, there is sufficient power supply and cooling of the pump laser diodes in all fibre lasers.

Laser and pump light in light wave ladders

The light is led through the glass fibres, with the inner cross-sectional area being the laser -active medium. There are also rare earths there. The energy supply is over Laser diodes, so -called pump diodes, that radiate on the fibre from the outside. In this area, the core of a fibre laser surrounded by a pump coat. If an energetic suggestion occurs, light signals can be transmitted by long and thin strands that consist of pure glass. In this way, the light of the laser is increased in many ways. In this context, it is important to know that a fibre can act not only as a guide system for the beam of light, but also as a resonator. Individual fibres are able to generate laser beam performance of 100 W or more, whereby the quality of the radiation is generally very high. If the rays are also bundled and the efficiency is high, a significantly higher radiation performance can be achieved in many cases.

Fibre laser - powerful and flexible

Fibre lasers are robust, flexible and resilient. It can be assumed that they work perfectly under normal conditions for several thousand hours. Also, are Fibre laser relatively insensitive to contaminants Or mechanical vibrations. All of this makes a decisive contribution to the fact that they can be used flexibly in industry, medicine and in many other areas. Every pump diode contained in a fibre laser is spatially separated by the other pump diodes and has its own heat sink. This is an essential prerequisite for robustness and the long service life of a fibre laser.

Where can a fibre laser be used in practice?

The possibilities of fibre lasers are very diverse. Basically, they are possible wherever small structures are engraved or high -resolution images and labels have to be attached. In the case of large surfaces, there is an advantage that the volume of the fibre optics used only has to be very low. Furthermore, effective cooling is ensured at all times. In this way, the laser can be used over a longer period of time without any major interruptions. The efficiency is relatively high, while the maintenance effort for the laser is low. The laser produces very little waste heat at the output.

Fibre laser in medicine, industry and construction

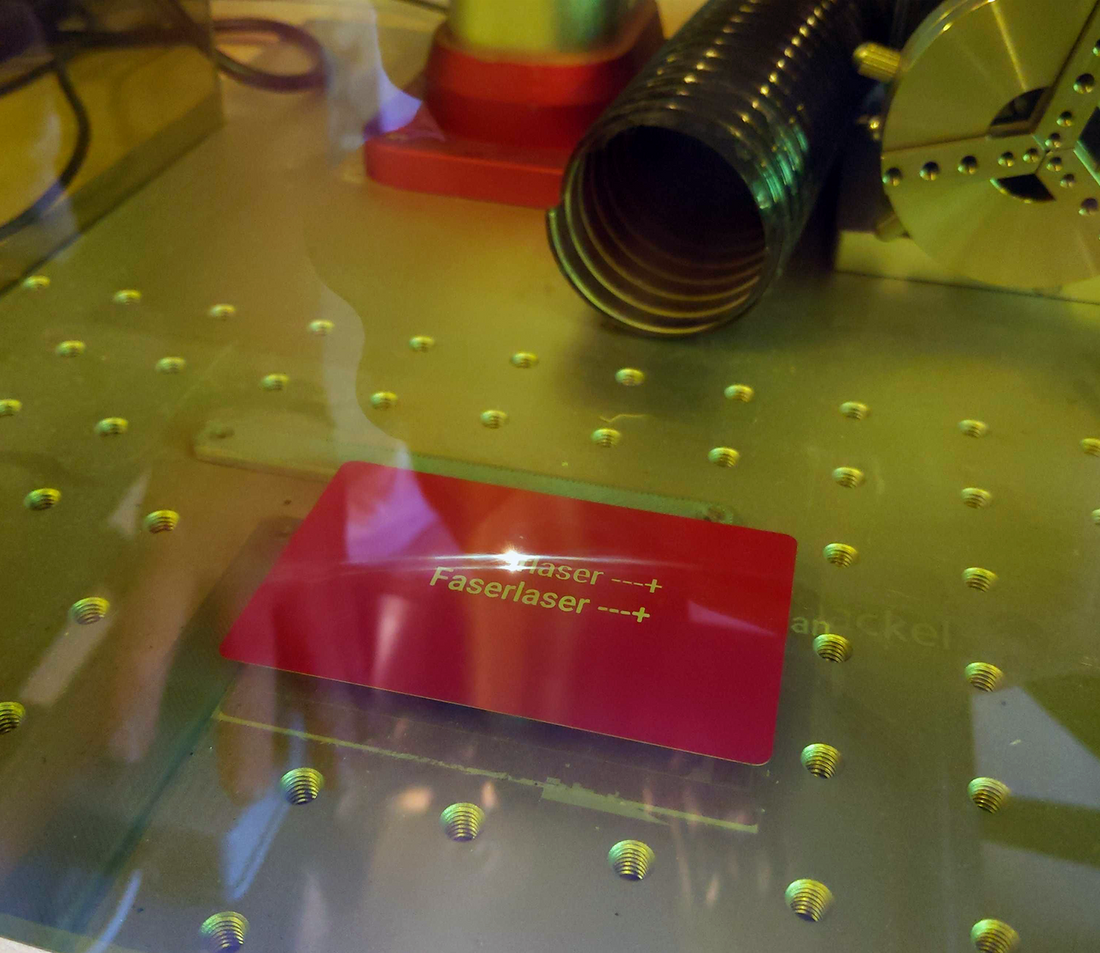

Harder materials such as metals or Plastics can be processed very quickly and reliably with fibre lasers. You can also label components or mark products. The marking in particular is very quick, whereby no compromises regarding precision have to be made. Rather, the opposite is the case, because the fibre laser is able to combine rapid speeds when marking with an extraordinarily high precision. For this reason, he comes also used very often in medical technology. Even if you want to label very thin and sensitive foils, it is laser Excellent. You can rely on the fact that he will make the label very filigree, permanently and without any damage to the film. In this context, it is important to know that labelling in the industrial area can be done without touching the surface and extremely economical.

Advantages and disadvantages of a fibre laser

The use of fibre lasers proves to be advantageous in many areas. The radiation quality is very high, and the performance is impressive. There is also good efficiency. Even if the laser has to edit larger surfaces, good cooling is always guaranteed. With the fibre laser you can mark large areas within a very short time. Because of its robustness and its special properties, the Fibre laser largely maintenance -free And can be used over a very long period of time.

Fibre laser is only available with a wavelength in the range of 1064 Nm. - This is very advantageous when processing metal. At the same time, the use of fibre lasers, due to the wavelength, is limited to certain materials. So the fibre laser is not suitable for laser cutting From materials such as acrylic, wood and textiles. The laser beam cannot be absorbed here due to the wavelength of 1064 Nm. As a result, there is no interaction between the light and the organic material. In addition, high-performance fibre lasers usually belong to laser class 4. Therefore, are special protective measures necessary. Use of fibre lasers without a laser protection officer is not permitted. Of course, safety glasses have to be worn all the time, since the rays for the eye and the skin are dangerous. If the laser is handled incorrectly, there is also a fire risk.

Mr Beam Laser cutter as an alternative to the fibre laser

You don't necessarily want to cut metal with a laser? Is constant security particularly important to you when it comes to lasers? Then it is Mr Beam Laser cutter Exactly the right tool for you! Of the Mr Beam can cut and engrave many materials like wood, felt, Acrylic, Foam and leather. But that's just a small selection. The Laser applications with the Mr Beam are really diverse. Engraving metal It is also possible with the help of the Marksolid laser marker spray! The Lasermachine belongs to laser class 1. - No laser protection officer is necessary. There is also a separate one Laser cutter software that is intuitive to use. If you want to learn more about our laser cutter, you can easily Book a free demo date or us Contact directly.