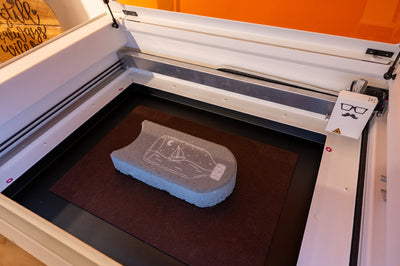

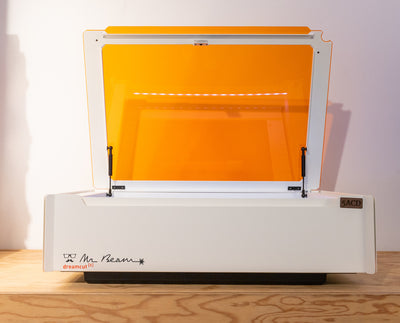

Besuche uns in unserem Showroom in München und erlebe den Mr Beam live. Wir zeigen dir persönlich unseren Lasercutter und beantworten deine Fragen. Gerne kannst du auch Materialien und Dateien (auf USB-Stick) zum Testen mitbringen. Wir freuen uns auf dich!

![Mr Beam dreamcut [x] Lasercutter](http://www.mr-beam.org/cdn/shop/files/mr-beam-dreamcut-x-laser-hero.jpg?v=1704362921&width=2400)